Discount wholesale Carton Printing Machine - Full-Auto Heat Transfer Screen Printing Line – VTEX GROUP

Discount wholesale Carton Printing Machine - Full-Auto Heat Transfer Screen Printing Line – VTEX GROUP Detail:

Full-Auto Heat Transfer Screen Printing Line

This production line are upgrade modeles from swing cylinder printing machine recent years. this kind of machine has adopted classical “stop-cylinder” printing movement instead of the original “reciprocating movement”. therefore, it not only ensure the paper accurate position before scratch-print, but also reduce the producing waster rate. beside, there is little impact with such high speed and revolving, which also improves the register precision.

Optional Equipment:

1、anti-static device & sheet cleaner

2、front pick-up feeder

3、vacuum pump in German or Chinese

4、feeder head in Heidelberg or Normal

5、non-stop pre-heap paper device

6、pull/push side guide

7、squeegee knife holder servo system, ink pneumatic device

8、can order min size paper A4 (297mm X210mm)

|

ITEM CODE |

XH-720 |

XH-800 |

XH-1020 |

XH-1050 |

| MAX PAPER SIZE(mm) |

720×520 |

800×600 |

1020×720 |

1050×750 |

| MIN PAPER SIZE(mm) |

350×270 |

350×270 |

560×350 |

560×350 |

| MAX PRINTING AREA(mm) |

720×510 |

800×590 |

1020×710 |

1050×740 |

| PAPER THICKERNESS (G/SQM) |

90-250 |

90-250 |

120-350 |

90-420 |

| PRINTING SPEED(SHEET/HOUR) |

500-3500 |

500-3500 |

500-3000 |

500-4000 |

| TOTAL POWER(kw) |

9 |

11 |

12 |

12 |

| TOTAL WEIGHT(kg) |

3500 |

4000 |

5200 |

5500 |

| EXTERIOR(mm) |

3000×2240×1680 |

3500×2480×1710 |

3900×2900×1800 |

3800×3110×1750 |

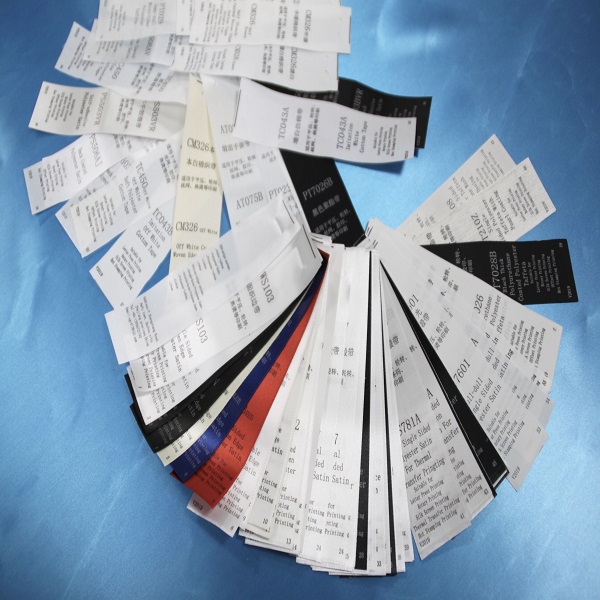

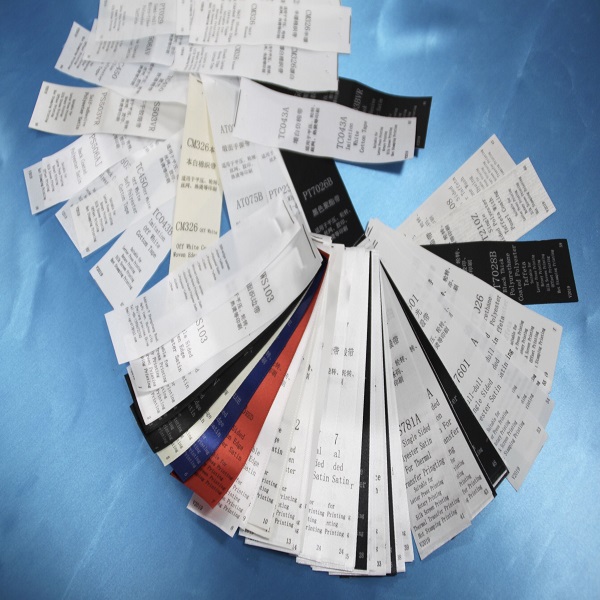

Product detail pictures:

Related Product Guide:

We're going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Discount wholesale Carton Printing Machine - Full-Auto Heat Transfer Screen Printing Line – VTEX GROUP , The product will supply to all over the world, such as: Peru, Cairo, Ukraine, We've been consistently broadening the market within Romania in addition to preparation punching in extra premium quality merchandise connected with printer on t shirt so that you can Romania. Most people firmly believe we've the whole capacity to provide you happy solutions.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!