Label Screen Printing Machine - Flexo Printing Machine With Three Die-cutting Stations – VTEX GROUP

Label Screen Printing Machine - Flexo Printing Machine With Three Die-cutting Stations – VTEX GROUP Detail:

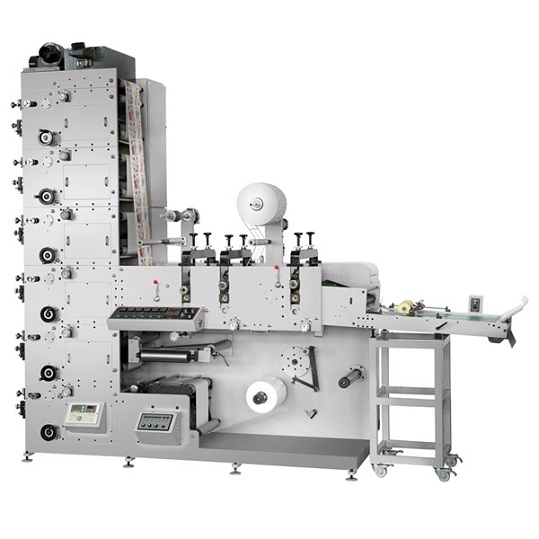

Flexo Printing Machine With Three Die-cutting Stations

Main Features

1.Adopt the ceramic anilox cylinder to transfer the ink.

2.Each printing unit adopts 360° plate-adjustment.

3.Three die-cutting stations, the first and second die-cutting station can do double sides working, the third die-cutting station can be used as sheeter.

4.Computerized web-guiding system is installed in the front of printing unit,it ensures the material always in the right position. (standard configuration)

5.After sheeting in the third die-cutting station, conveyor belt can output the products orderly. (option)

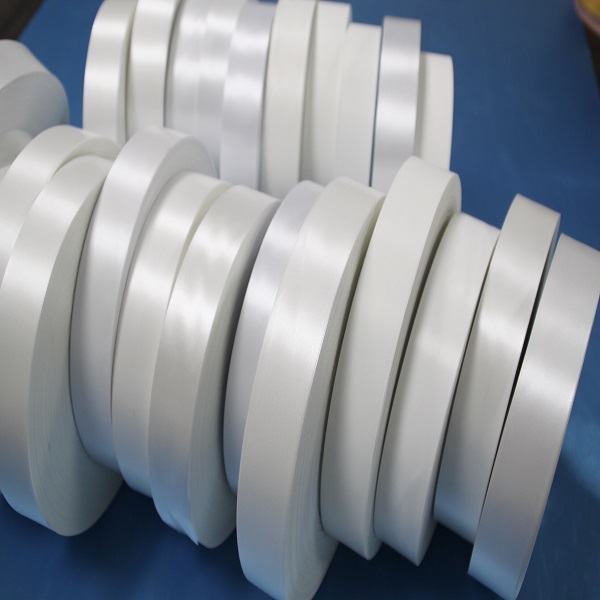

6.Unwinding and rewinding tension are auto-controlled by magnetic powder, two rewinders is possible in this machine.

7.Video inspecting system is an option, it can watch the printing quality when in high speed.

8.The ink rollers will be separated from the printing roller, and keep running when the machine stops.

9.Main motor use inverter to adjust stepless speed.

10.The machine can finish material-feeding, printing, varnishing, drying, laminating, die-cutting, rewinding sheeter in a lump.It is an ideal machine for printing adhesive labels.

| Model: | XH-320G |

| Printing speed: | 60M/min |

| Printing chromatic number: | 1-6colors |

| Max. web width: | 320mm |

| Max. printing width: | 310mm |

| Max. unwinding diameter: | 650mm |

| Max. rewinding diameter: | 650mm |

| Printing length: | 175-355mm |

| precisions: | ±0.1mm |

| Dimensions(LxWxH): | 2.6(L)x1.1(W)x2.6(H)(m) |

| Machine weight: | about3350kg |

Unwinding and Rewinding Tenstion are Auto-controlled by Magnetic Powder

Unwinding and Rewinding Tenstion are Auto-controlled by Magnetic Powder Web-guider

Web-guider Three Rotary Die-cutting Stations

Three Rotary Die-cutting Stations

Note:*=Options

* UV Dryer System

* UV Dryer System * Sheeter Conveyer

* Sheeter Conveyer

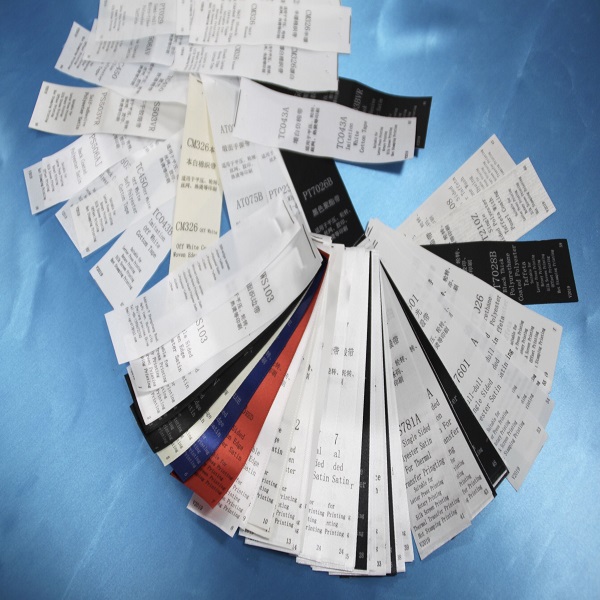

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for Label Screen Printing Machine - Flexo Printing Machine With Three Die-cutting Stations – VTEX GROUP , The product will supply to all over the world, such as: Pretoria, Provence, Bolivia, Products have been exported to Asia, Mid-east,European and Germany market. Our company has constantly been able to update the products performance and safety to meet the markets and strive to be top A on stable quality and sincere service. If you have the honor to do business with our company. we will definitely do our very best to support your business in China.

This manufacturer can keep improving and perfecting products and service, it is in line with the rules of market competition, a competitive company.